If you have Sellenatela shoes, look around the top of the heel. Is there a small "hole" that is inconspicuous?

Actually, this hole is a proof that it is handmade. It is a remnant of the craftsman's use of nails to fix the shoes to the wooden pattern when performing the work called "tsurikomi".

All Sellenatela shoes are made by Japanese shoe craftsmen. Leather shoe making is one of the local industries in Taito Ward, Tokyo, and many Japanese leather shoe factories are located in downtown Tokyo, near Asakusa.

This is Apollo Co., Ltd. , a shoe manufacturer in Higashi Nippori, Arakawa Ward. It is one of the essential manufacturers for Sellenatela shoe making.

The Japanese shoe industry has a thorough division of labor. Each material (shoe material) and each process are handled by different companies, which is actually very complicated. Here at Apollo, we offer a one-stop service from shoe planning to manufacturing. This time, thanks to Mr. Apollo's kindness, I was able to cover all the processes involved in shoe making, from planning to manufacturing. We will introduce the back side of shoe making that you can't usually see.

Let's start with the shoe making process.

At Sellenatela, designer Enomoto thinks of a seasonal theme and draws a design picture. Once the design has been decided, we decide on a model called a "shoe model" that will serve as the prototype for the shoe.

Every season, Enomoto kindly consults with us on how to create the shape of the shoes that he envisioned in his head.

Mr. Yuzawa, in charge of Apollo's Sellenatela. A reassuring ally who works with Enomoto to shape the designs that Enomoto envisions every season. Please respond positively to unreasonable challenges.

The type of shoe to be made is a very important process, as it affects not only the form of the shoe, but also its ease of wear and fit.

Once the wooden pattern is decided, the planner (pattern maker) creates a paper pattern based on the design drawing drawn by designer Enomoto. Making a paper pattern is a complicated process. First, tape is attached to the wooden pattern, and the shoe line is drawn on it.

Then, the tape is cut along the line and peeled off, and each part is dropped onto a flat surface.

Even if you take a single paper pattern for shoes, there are so many parts, and even if you make just one pair of shoes,

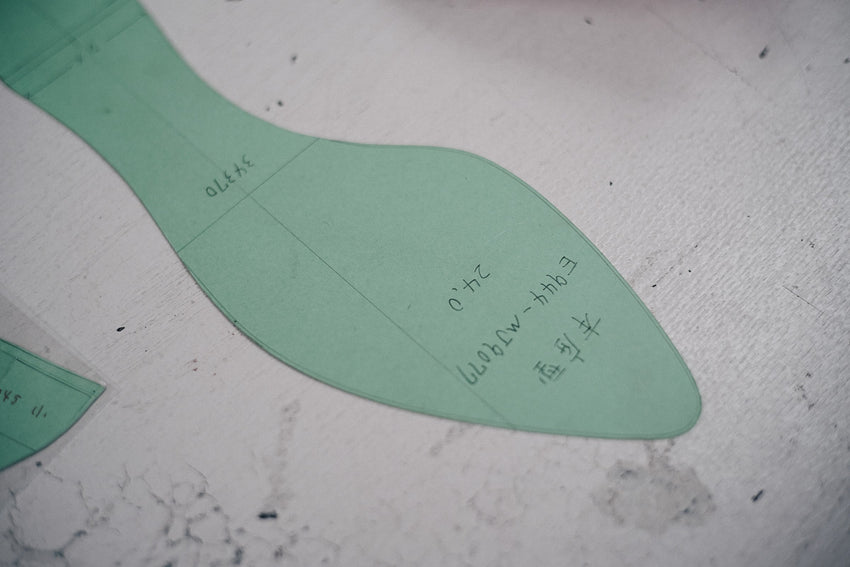

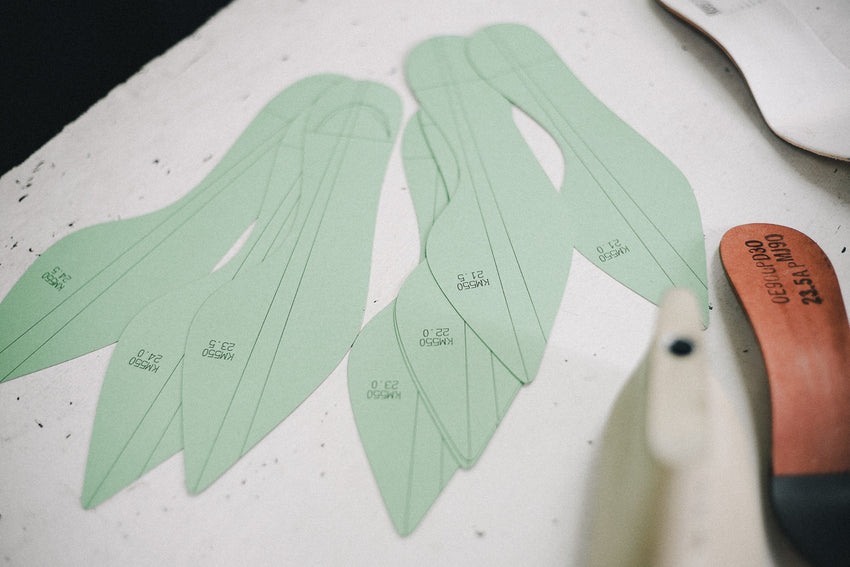

And I need 5 paper molds. On top of that, we have to arrange them by size, so it's a lot of work...!

A mold called a “cutting mold” is made based on the paper mold, and the upper and lining leather are cut with a cutting machine. This work is sometimes handled by a “cutting shop” who specializes in cutting.

Cutting dies prepared by size.

Here is the cutting machine.

Apply pressure in several steps from the top and cut.

The cutting machine is only used for mass production, and when making samples, we cut each piece by hand without using the cutting machine.

The cut upper and lining leather are sewn together with a sewing machine to create a shape. In some cases, this work is also handled by a “kouya-san” who specializes in making armor.

Apollo is one of the Japanese shoe makers that actively employs young staff. The appearance of young craftsmen working shoulder to shoulder with veteran craftsmen stands out.

Inside the factory where threads and machines are lined up. Work continues silently.

Each part of the shoe is made by wrapping leather around the heel, and wrapping leather around the part that is slightly visible when the insole is pasted on the insole (insole wrapping).

We also found HELENA [SILVER] and HELENA [REDDISH BROWN] , the new works of the 17AW COLLECTION in production!

![HELENA [SILVER]](http://cdn.shopify.com/s/files/1/2036/3279/files/sellenatela-stories02-30_850x850.jpg?v=1503538203)

![HELENA [REDDISH BROWN] and HELENA [SILVER] under construction](http://cdn.shopify.com/s/files/1/2036/3279/files/sellenatela-stories02-26_850x850.jpg?v=1503535774)

This is the HELENA [SILVER] insole that has completed the insole winding. Can you see that the edge part is wrapped with silver leather? Other than the leather-wrapped part, it's usually hidden between the insole and the outsole, so it's a part you don't often see.

![HELENA [SILVER] insole with completed insole winding](http://cdn.shopify.com/s/files/1/2036/3279/files/sellenatela-stories02-27_850x850.jpg?v=1503535959)

Each process is carefully carried out by the hands of specialized craftsmen.

Inside the factory, there are wooden patterns that are essential for shoe making.